Temperature profile measurements and analysis

The high-quality temperature measuring systems we supply are produced by PhoenixTM and are used for temperature profile measurements and temperature analysis in industrial ovens. The sectors where the temperature measuring systems are often used are:

Automotive; Food; Gas; Metal; Ceramic industry;

Rock and Glass Wool; Heat Treatment

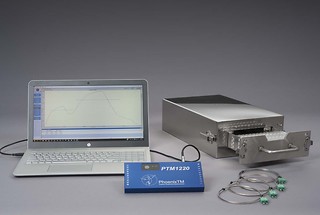

A complete temperature measurement system consists of a heat-resistant thermal barrier, a data logger, temperature sensors and software. The often-used combinations of these products that are specifically composed for sectors or a certain temperature range can be found further on this page. An overview of the possibilities of temperature profile measurements, analysis and the products can be found in the PhoenixTM brochure.

We supply parts of the system as well as a complete combination.

We would gladly come in contact with you to discuss the possibilities. Please use the button below to get in touch with one of our employees or view the contact options on our contact page.

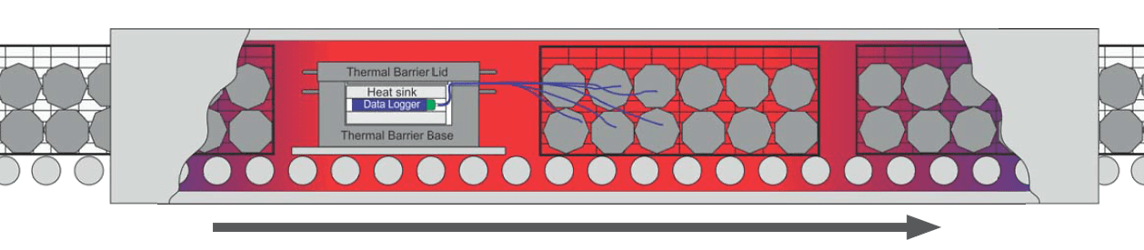

How it works

The temperature measuring system with connected thermocouples moves with the product through the various temperature segments in the oven, whereby the electronics of the data logger are protected by a robust, specifically selected, metal thermal barrier. The temperature sensors are placed near, on or in the product and can, for example, be provided with a magnet or clamp. The system can be easily applied during operation and gives an exact, retrospective or even real-time view of the thermal furnace process. This way you can assure your customers of excellent quality control at any time.

The heat-resistant thermal barriers are available in various sizes and types to meet specific sector and temperature requirements. The data loggers are available in versions with 6, 10 or 20 measuring points with thermocouple types K, N, R, S, T, J and B or even with a combination of thermocouple types. An ATEX certified system is available for explosive environments. There is also the possibility to send live data directly during process to your device through a wireless connection. This way you can monitor and / or adjust the temperature progression live.

The "ThermalView" software provides an extensive documented insight into the measurement data and is very user-friendly and focused on practical situations. ThermalView is available in a number of configurations to meet the requirements of various industrial applications, including a configuration to generate AMS2750 and CQI-9 reports.

combinations temperature Measuring systems

FIS04 ATEX system; Intrinsically safe temperature monitoring system

Telemetrie Series 1000 temperature measurement system with wireless live monitoring

HTS01 systems for processes with temperatures up to 800 °C

HTS02 systems for processes with temperatures higher than 800 °C

HTS03 systems for processes with temperatures higher than 1000 °C

HTS05 systems for ovens in the Ceramic Industry

HTS06 systems for Aluminium processes

HTS07 systems for reheat processes in the Steel Industry

HTS08 systems for Aluminium Brazing applications

HTS12 systems for heat treatment processes with integrated oil quench

FOS14 systems for Food processes up to 250°C

FIS04 systems for paint and powder coating processes up to 300°C

Are you interested in or do you have questions about our temperature measuring systems? We would like to get in touch with you. Please call us via telephone number +31 (0) 343-595410 or send us an e-mail to info@ltbv.nl. Of course you can also use the button below.

Popular Pages

Products Resistance Thermometers (-200 °C to 850 °C) Thermocouples (up to 2300 °C) ATEX temperature sensors Specials Temperature measurement systems Temperature transmitters Compensation and thermoelectric cables Digital Indicators Individual components News Industries About us Technical InformationConsultation about your temperature measurements? We'll call you back.

DIRECT CONTACT WITH OUR TEAM

Langkamp Technology B.V.

22 Molenvliet

3961 MV Wijk bij Duurstede

Netherlands

Phone: +31 (0)343-595410

info@ltbv.nl