Technical Information

13. Connection types of sensor resistances

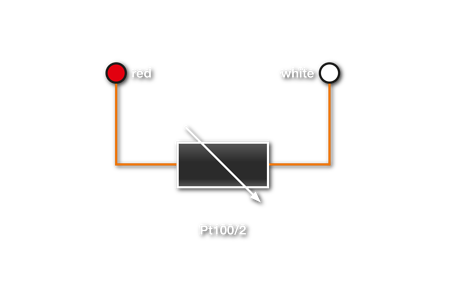

a. Two wire circuit

The sensor has two connections, at which a two-core cable connection is attached for control. The problem here is that the conductor possesses an electrical natural resistance, which increases the total resistance and thus – depending on the length of the conductor- leads to a more or less excessive measurement result.

In order to compensate for this, the conductor resistance must be determined and entered into the control as a correction size. In practice resistance thermometers with 2 wire switches, due to the fact described, rarely lead to exact measurement results. The natural resistance of the conductor changes also with changed ambient temperature and/or air humidity.

These resistance thermometers therefore are only used for measurements, with which a tolerance of some degrees is insignificant, e.g. with cooling water.

With high ohmic sensor resistances (Pt500, Pt1000) the measuring error is reduced by the factor 5 and/or. 10, so that this - under the described circumstances- leads to somewhat more exact measurement results.

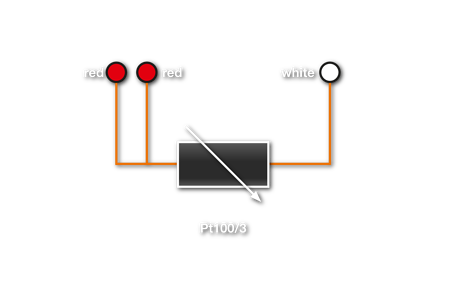

b. Three wire circuit

Resistances in three wire technology function exactly the same as sensors in two wire circuits, however an adjustment of the conductor resistance is not necessary:

An additional wire is connected to a connection of the sensor resistance. Thus a second measuring circle develops, which represents the actual conductor resistance at any time. In the control, this value is now taken off from the value of the measuring circle with resistance and the actual resistance of the sensor is determined.

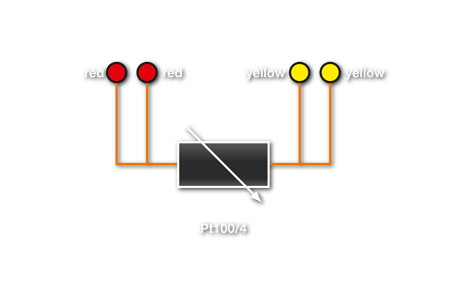

c. Four- wire circuit

in contrast to the three-wire circuit, where only the conductor resistance of one of the two feeds is determined, while with the four wire circuit the resistances of both feeder lines to the resistance are determined. The measurement results are consequently also always accurate if the feeds should have different natural resistances.

Popular Pages

Products Resistance Thermometers (-200 °C to 850 °C) Thermocouples (up to 2300 °C) ATEX temperature sensors Specials Temperature measurement systems Temperature transmitters Compensation and thermoelectric cables Digital Indicators Individual components News Industries About us Technical InformationConsultation about your temperature measurements? We'll call you back.

DIRECT CONTACT WITH OUR TEAM

Langkamp Technology B.V.

22 Molenvliet

3961 MV Wijk bij Duurstede

Netherlands

Phone: +31 (0)343-595410

info@ltbv.nl